Rosco’s LugNet Page

These pages are no longer updated. You can view my LEGO related pages here.

All images hosted by Brickshelf L.L.C. but who knows how long that will last.

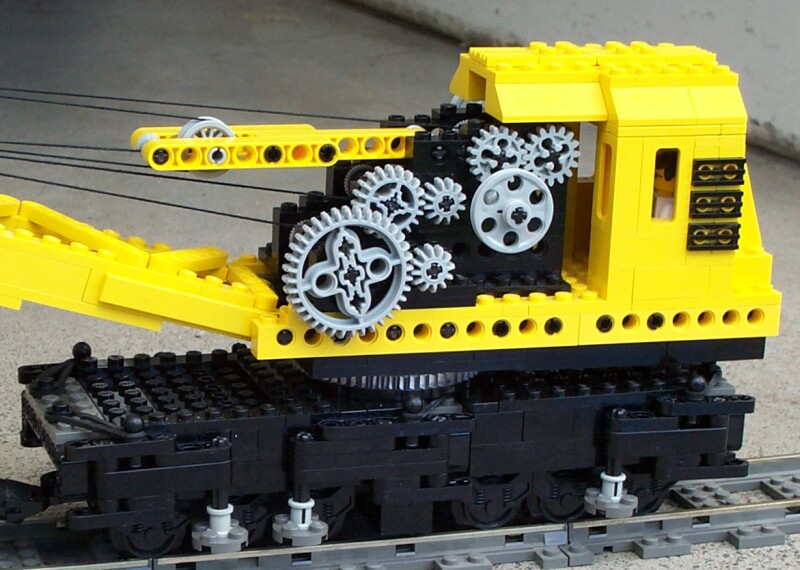

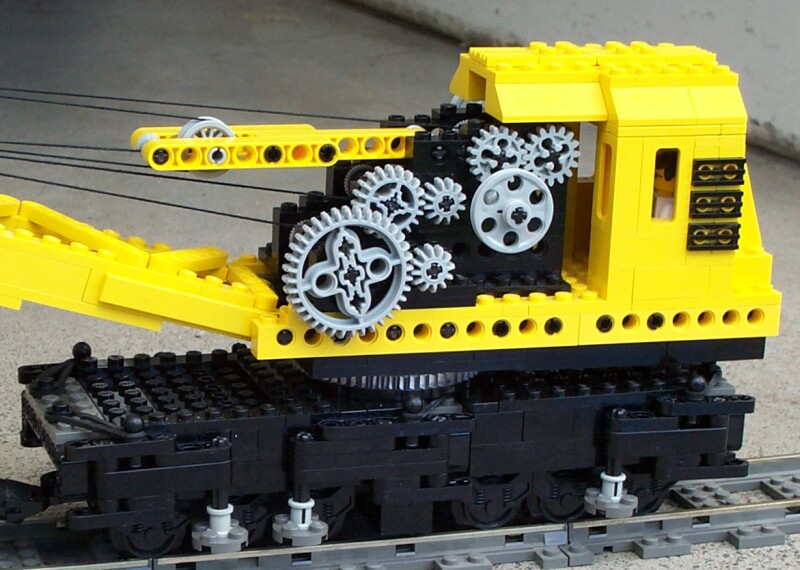

Breakdown Crane

| | Click picture for more information on Crane 31

|

Well, with my LEGO interest regularly moving between cranes & trains, I thought the ideal way to satisfy both needs would be to build a breakdown crane. So I started searching for good candidates, I wanted it to be fairly big, but when I came across “Crane 31” restored in Western Australia by the Pemberton Tramway Company, I thought, even though it’s fairly small by today’s standards, the local historical interest was more than enough to convince me to tackle it.

Crane 31 was originally steam powered, but was later converted to diesel power. When it reached the end of it’s useful life, it was written off by the W.A.G.R. until the PTCo successfully bid to purchase it. After restoration, it is now regularly used to re-coal their steam locomotives, and occasionally gets to do more interesting stuff, like helping install turntables and other neat stuff.

My rendition is based on the restored diesel crane. The main outward difference from the steam powered version is small exhaust pipe on the rear of the cab, as against the large exhaust funnel on the steam version. Note that the power plant only operates the crane functions - large breakdown cranes are rarely self-propelled, and must be pulled (or often pushed) to the required site by a locomotive.

Carrier

| | The first requirement was for a solid, stable carrier. “Crane 31” is carried by a flat car with 2 3-axle bogies. This spreads the load enough to allow it’s use on most lines in Australia. My car is based on a standard 6x24 stud train base, but is strengthened with an extra layer of bricks on top. It has also been extended to 8 studs wide - this was mainly to accommodate the technic turntable nicely. It also has a train weight under the centre, partly for stability during transport, and partly to provide a little extra ballast for lifting.

|

Outriggers

| | “Crane 31” has 6 outriggers - 2 main ones, attached at the centre of each side of the carrier, and 4 smaller ones attached near each corner. All 6 are hinged at the point of attachment, and are rotated around against the side of the car for transport.

My outriggers are all attached with a sturdy technic construction, providing plenty of strength to stabilise the crane. The 2 main outriggers can easily carry the entire weight of the crane. They also have extendable pad jacks, although they can only extend about 1 stud, and only have the friction of an axle in a cross-hole to hold them up.

I have also fitted rubber bands to all 6 outriggers to hold them in the 2 required positions - fully retracted or fully extended.

|

Superstructure

Again for this model I have decided to use my standard technique of hose reels to provide friction for the crane functions. This crane has 4 functions: slew, luff, and hoist for 2 hooks.

Slew is provided by a technic turntable. Again, it is solidly attached to the carrier, but can be fairly easily parted from the superstructure.

Luffing is provided by a 4-part pulley attached near the top of the boom.

The 2 hooks have separate hoist lines. The main hook uses a 4-part line, and 3:1 reduction on the pulley, so it hoists fairly slowly, but can lift and hold a fairly large weight.

The auxiliary hook line is 2-part, and has 5:3 reduction, so is faster, but cannot hold as much weight. It is also at a larger radius, and attached to the extended portion of the boom, reducing its weight limit even more.

The superstructure has 3 train weights attached underneath it for ballast.

Boom

| | The boom of this crane is significantly different from most modern mobile crane booms. The longish extension, beyond the point where the luffing arm is attached, required the obviously thicker portion around the bend in the boom, in order to be able to lift large loads.

Because LEGO isn’t great for modelling curvy bits like that (but it’s getting better), I decided to cheat a little with the boom extension. The load is actually borne by an internal technic frame, and the yellow facade is just that - it doesn’t carry any load at all.

| |

|

I decided fairly early to make the boom 5-wide. This width looks reasonably good, and allowed for 2 important structural elements:

- The 3-wide internal technic frame mentioned above, and

- the use of 6L technic liftarms for diagonal bracing.

The technic frame was not trivial, as it needed to:

- Provide a solid extension the correct length and at the correct angle;

- Have room available at the required points for the hoist pulleys and cable tie-offs; and

- Not foul the hoist cables.

| | After much experimentation, I found a frame that fitted all those requirements - here is a render of it, and a pic of the real thing with part of the facade removed.

|

Cab

| | The cab is fairly simple, and contains the controls for the crane, and a seat for the operator. The diesel engine is at the rear, covered by the sloped cowling. I wanted to model it, but couldn’t come up with a design that looked good, so cheated and just modelled the cover.

|

Match car

| | Most breakdown cranes have a modified flat car coupled to them. It carries rigging equipment, extra sleepers (commonly used under the outrigger pads), and may even carry extra ballast for larger cranes.

The match car is so called because each one is generally purpose built or modified to “match” it’s particular crane.

My match car is a pretty simple 8-wide flat car, and includes a pedestal which carries the boom while travelling, and some storage room for rigging gear. The pedestal has to rotate and allow the boom to slide as it negotiates corners, and also has a hitch point for the main hook. The auxilliary hook swings free while travelling.

|

Lift test

| | Well as with other cranes I’ve built, I gave this one a bit of a test, to see how well it worked. As you can see, it lifted my “N” class loco, however I did need to lock the luffing spool in place to stop it turning. I was quite pleased though - that loco is pretty heavy, as it includes a weight brick and a technic motor!

|

References

30 ton Cowans Sheldon breakdown crane

60 ton Cowans Sheldon breakdown crane

Pemberton Tramway Company

My Brickshelf folder

|

|

Site last modified November 4, 2004 Home

|