|

Ross Crawford / projects / allterraincrane | |

| Rosco’s LugNet Page These pages are no longer updated. You can view my LEGO related pages here. All images hosted by Brickshelf L.L.C. but who knows how long that will last. All Terrain Crane

Specifications Carrier

Superstructure

Optional Equipment

Details Carrier The carrier has 2 main functions; the 4 outriggers, and steering on 4 axles. The outriggers are just 1x10 bricks with 1x8 tile on top, and an extra 1x2 tile to stop them sliding out too far. They are able to carry the weight of the crane itself, but not much more, so I usually attach some bricks underneath the chassis to hold the crane up while working.

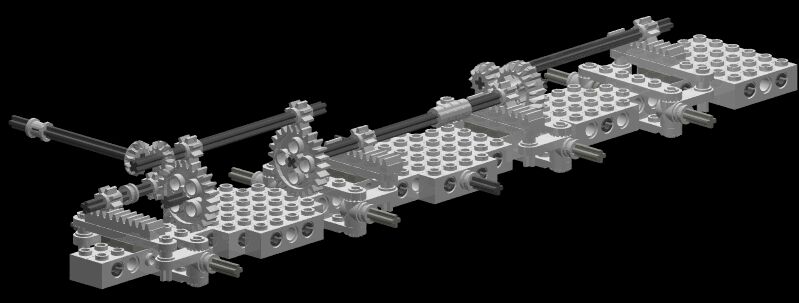

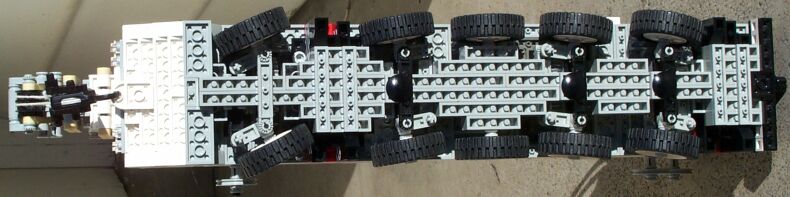

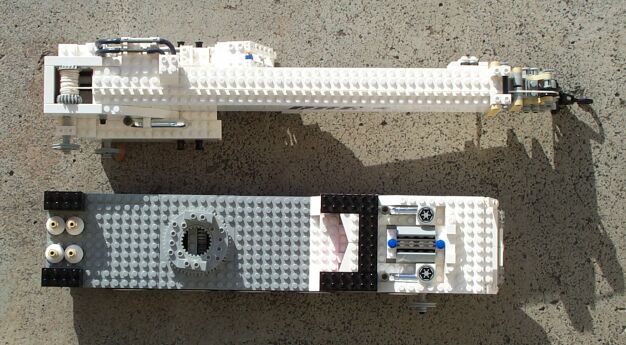

The steering geometry is not perfect, but it’s close. Axle 1 (front) turns 3 times further than 2 & 4, axle 5 turns 5/3 times further. To get the deck low enough, the 5:3 gears actually protrude up into the hole in the centre of the turntable! Note also the requirement to go “up and over” the outriggers between axles 1 and 2. This increased the backlash in the steering mechanism a little, but there was no other way around it. Note also that the steering control is on the side - I would have preferred the top, but the boom covers up too much of the top to allow it. Here is a view from underneath, with the wheels on full lock:

Superstructure

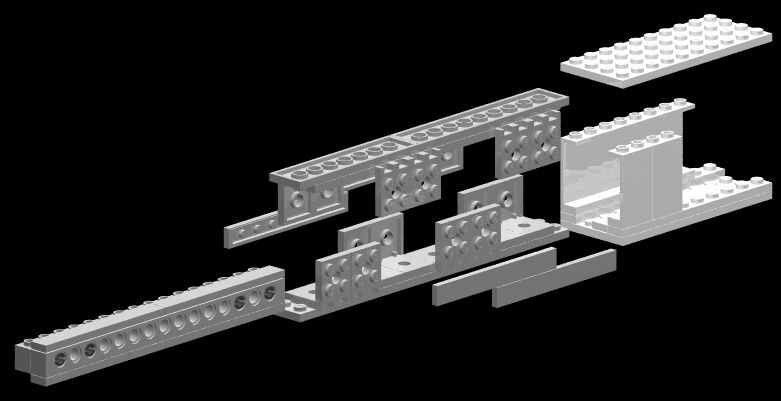

Extending the boom This is done manually, by pulling the innermost boom section. There is string which pulls the centre section out at half the rate, and pushes it back in. The discovery of how to do 2 telescopic sections in 4x4 cross section was the motivation for this crane. Here is an exploded pic of how it’s done:

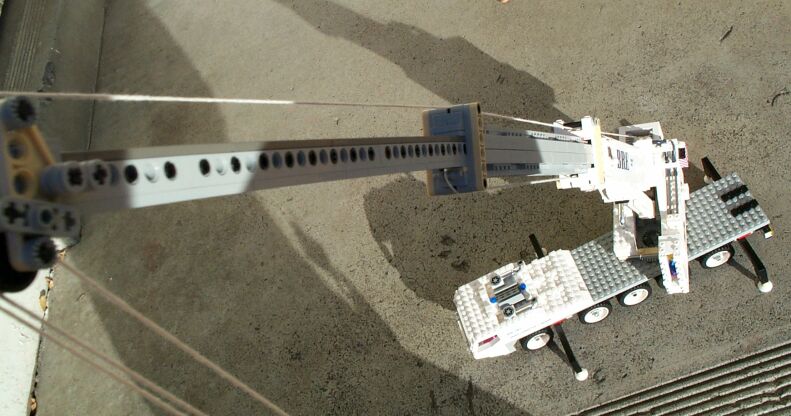

An interesting attribute of the construction is that the centre section is symmetrical - 5 plates (2 studs) square internal, 9 plates (3 bricks) square external; so it fits fine at 90 degree rotation, too. This gives the option of having “studs out” on top & bottom, instead of “studs in” as I’ve done here. It’s pretty rigid - you can see here a picture of it fully extended under load, and it doesn’t deflect as much as I thought it would. You can also see here one of the ropes used to synchronise the extension of the centre section. The other rope is totally enclosed inside the boom.

Compare this with the real thing:

The superstructure can be removed easily by pulling out 4 pins, and gently prising it loose from the turntable. Looking closely at the carrier, you can just see the 20 tooth double-bevel gear which protrudes into the centre of the turntable.

Optional Equipment

Load Test And finally, I thought I’d see how much load it could actually lift. Following Jennifer Clark’s lead, I decided to use canned food, in this case a 700g can of dog food. The lift was successful, but unfortunately the friction of the hose reels holding the boom up wasn’t quite enough, so I had to lock it in place. Note how much the elevating axle bends. And you can see by the picture that the turntable was under a fair bit of strain - I probably needed more ballast to make such a heavy lift safely. Also to put this in perspective, it’s only about half the weight of crane itself - the real crane could lift the equivalent of over 3kg... Anyhow, here are the pictures:

Here’s the brickshelf gallery with more shots (after moderation). Site last modified November 4, 2004 Home

|

|

Primary content in this document is © Ross Crawford. All other text, images, or trademarks in this document are the intellectual property of their respective owners. |

| |

©2005 LUGNET. All rights reserved. - hosted by steinbruch.info GbR |